Diffusion bonding is a solid-state joining process where stacks of plate or sheet are subject to changes in heat and pressure to create a facial weld between the materials.

Heatric first developed diffusion bonded PCHEs over 30 years ago, and has been continuously developing the diffusion bonding process since then. By pushing the boundaries of the technology, Heatric has been able to develop processes for bonding a number of stainless steels and related materials, including (but not limited to):

Each of these materials offers distinct benefits making them suitable for a diverse range of applications dependent on the requirements of the customer.

Heatric’s diffusion bonding technology allows for the joining of plates/ sheets in a range of configurations including varied heights and multiple-unit batches. This flexibility of process makes diffusion bonding suitable for a range of applications and Heatric has utilised the process for the manufacture of heat-exchangers, high-pressure valves, chemical reactors, cooling plates, solar absorbers and more.

For more information on Heatric’s diffusion bonding projects, and to understand how Heatric can help you achieve your project goals, send a message directly through the enquiry page or contact Heatric on:

+44 (0) 1202 627 000

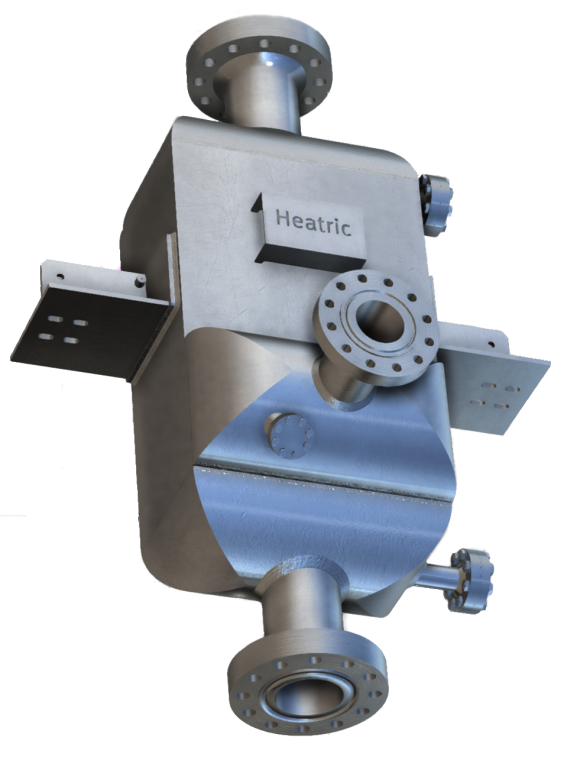

Heatric, a division of the Parker Hannifin Filtration Group, is a global leader in Printed Circuit Heat Exchangers (PCHEs). Heatric PCHEs are high performance, compact heat exchangers with applications across the energy industry; in oil and gas, power generation, marine, and clean technology systems. Each Heatric PCHE is bespoke to suit customer specifications and deliver maximum operational efficiency and performance. As technology pioneers with decades of design, manufacture

and operational experience, Heatric have the technical expertise to enable your innovation.

As bespoke manufactured products with fully integrated features, the inner workings of a Heatric PCHE are something that engineers rarely get an opportunity to see. This interactive 3D model allows the user to disassemble a Heatric PCHE to improve their understanding of the inner workings and components that make-up this robust, high-integrity technology.