From more than 30 years of experience in high-performance manufacturing, Heatric has developed expertise in a number of specialist areas that can meet the requirements and needs of a range of industries.

Heatric’s manufacturing resources and facilities include (but are not limited to):

Utilising the large number of resources available to the company, Heatric has worked on the following specialised manufacturing projects in addition to the manufacture of high-integrity heat exchangers:

For more information on Heatric’s specialised manufacturing projects, and to find out how Heatric’s expertise can support your project goals, send a message through the enquiry page or contact Heatric directly on:

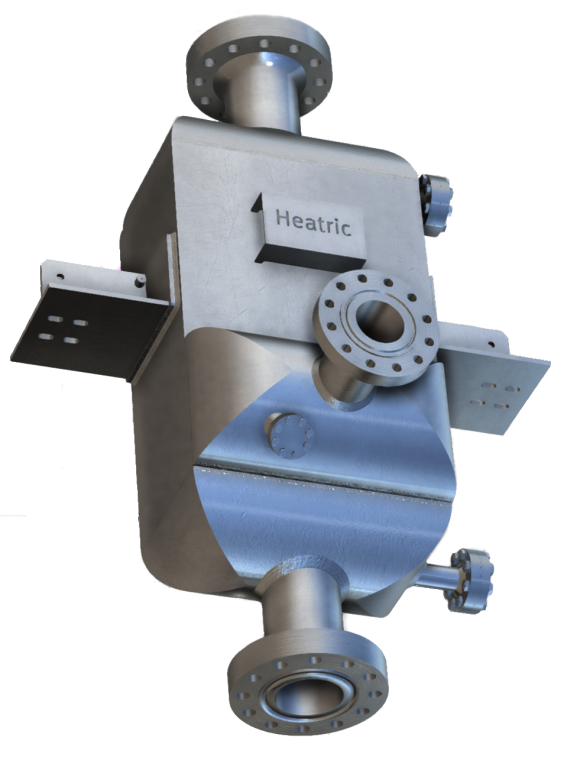

Heatric, a division of the Parker Hannifin Filtration Group, is a global leader in Printed Circuit Heat Exchangers (PCHEs). Heatric PCHEs are high performance, compact heat exchangers with applications across the energy industry; in oil and gas, power generation, marine, and clean technology systems. Each Heatric PCHE is bespoke to suit customer specifications and deliver maximum operational efficiency and performance. As technology pioneers with decades of design, manufacture

and operational experience, Heatric have the technical expertise to enable your innovation.

As bespoke manufactured products with fully integrated features, the inner workings of a Heatric PCHE are something that engineers rarely get an opportunity to see. This interactive 3D model allows the user to disassemble a Heatric PCHE to improve their understanding of the inner workings and components that make-up this robust, high-integrity technology.