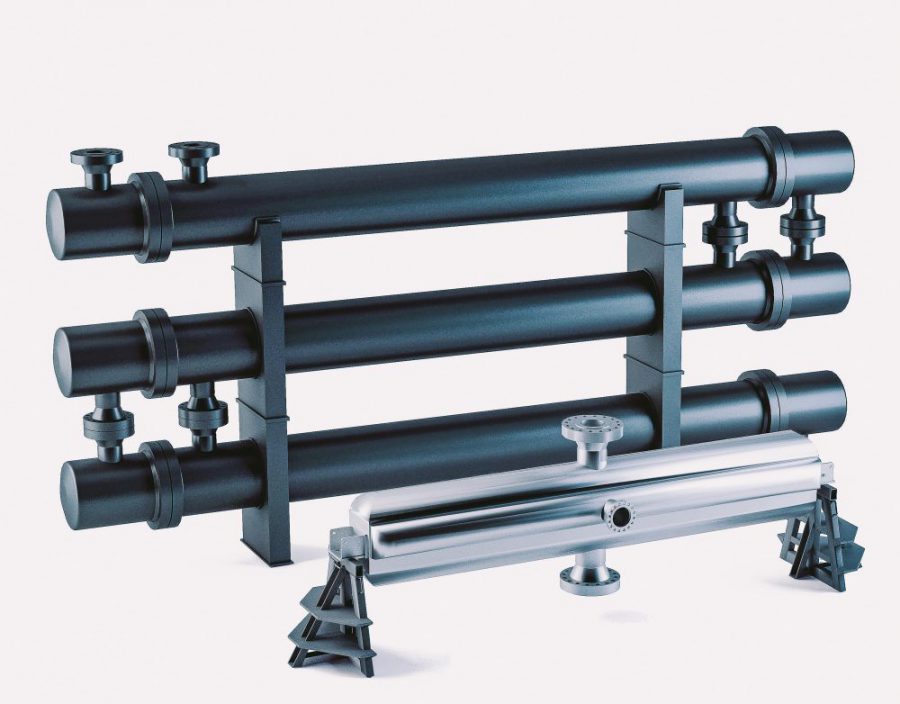

Heatric diffusion bonded exchangers bring significant benefits to floating processing facilities, as they can perform within a much lower size and weight envelope when compared to other heat transfer units such as shell and tube.

The significant savings in weight and space created by adopting diffusion bonded heat exchanger technology creates huge project savings in topside structural requirements and increased efficiency in space utilisation – a premium consideration in floating processing applications.

Their small size and weight also provides other operational project savings in terms of transport to site, handling, installation and a reduction in pipework requirements during connection to the processing train.

Due to their solid-state construction, diffusion bonded heat exchangers also bring a number of operational benefits to floating processing applications in terms of safety and the potential to combine multiple processes within a single unit if required.

Heatric has provided over 150 printed circuit heat exchangers for multiple duties in floating processing applications for companies such as Petrobras, Total and SBM.

Units supplied for these projects include:

For more information on the deployment of Heatric exchangers in floating processing applications, send a message directly through the enquiry page or contact Heatric on:

+44 (0) 1202 627 000

Heatric, a division of the Parker Hannifin Filtration Group, is a global leader in Printed Circuit Heat Exchangers (PCHEs). Heatric PCHEs are high performance, compact heat exchangers with applications across the energy industry; in oil and gas, power generation, marine, and clean technology systems. Each Heatric PCHE is bespoke to suit customer specifications and deliver maximum operational efficiency and performance. As technology pioneers with decades of design, manufacture

and operational experience, Heatric have the technical expertise to enable your innovation.