The high integrity, structural features, and characteristics created through Heatric’s manufacturing processes provide multiple safety features alongside a range of capital and operational cost savings. These inherent safety features include (but are not limited to) the following:

For for more information on the safety benefits of Heatric’s exchangers, and how they can support your project, send a message directly through the enquiry page or contact Heatric on:

+44 (0) 1202 627 000

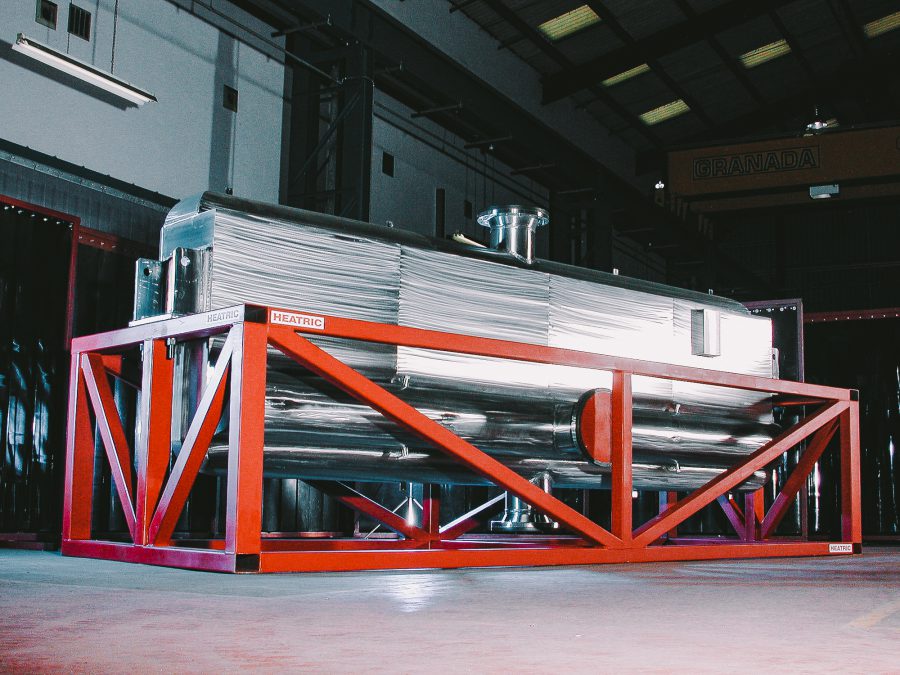

Heatric, a division of the Parker Hannifin Filtration Group, is a global leader in Printed Circuit Heat Exchangers (PCHEs). Heatric PCHEs are high performance, compact heat exchangers with applications across the energy industry; in oil and gas, power generation, marine, and clean technology systems. Each Heatric PCHE is bespoke to suit customer specifications and deliver maximum operational efficiency and performance. As technology pioneers with decades of design, manufacture

and operational experience, Heatric have the technical expertise to enable your innovation.