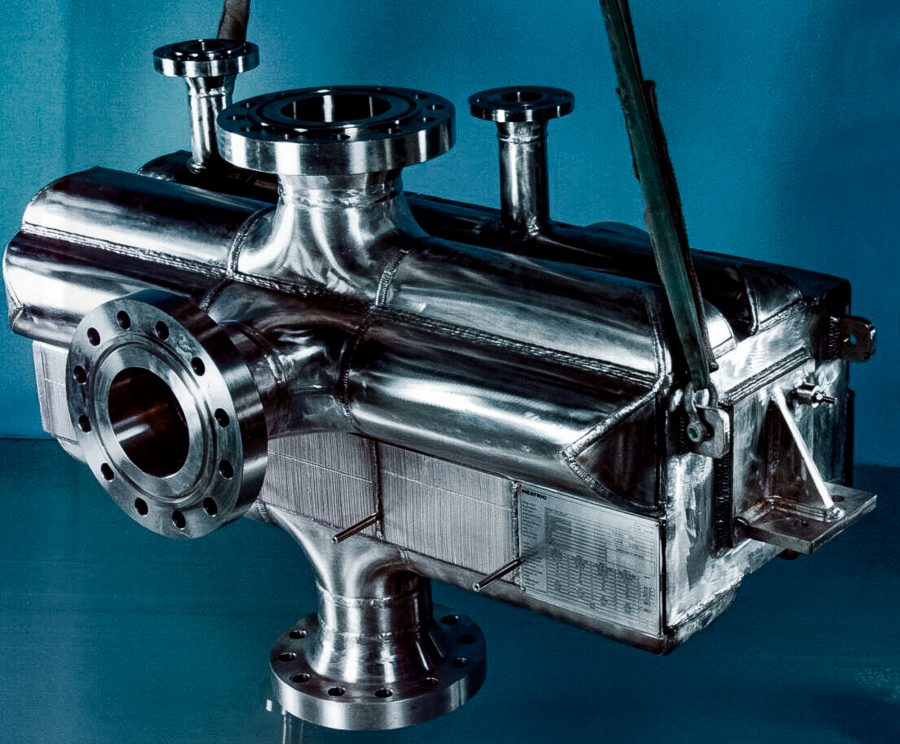

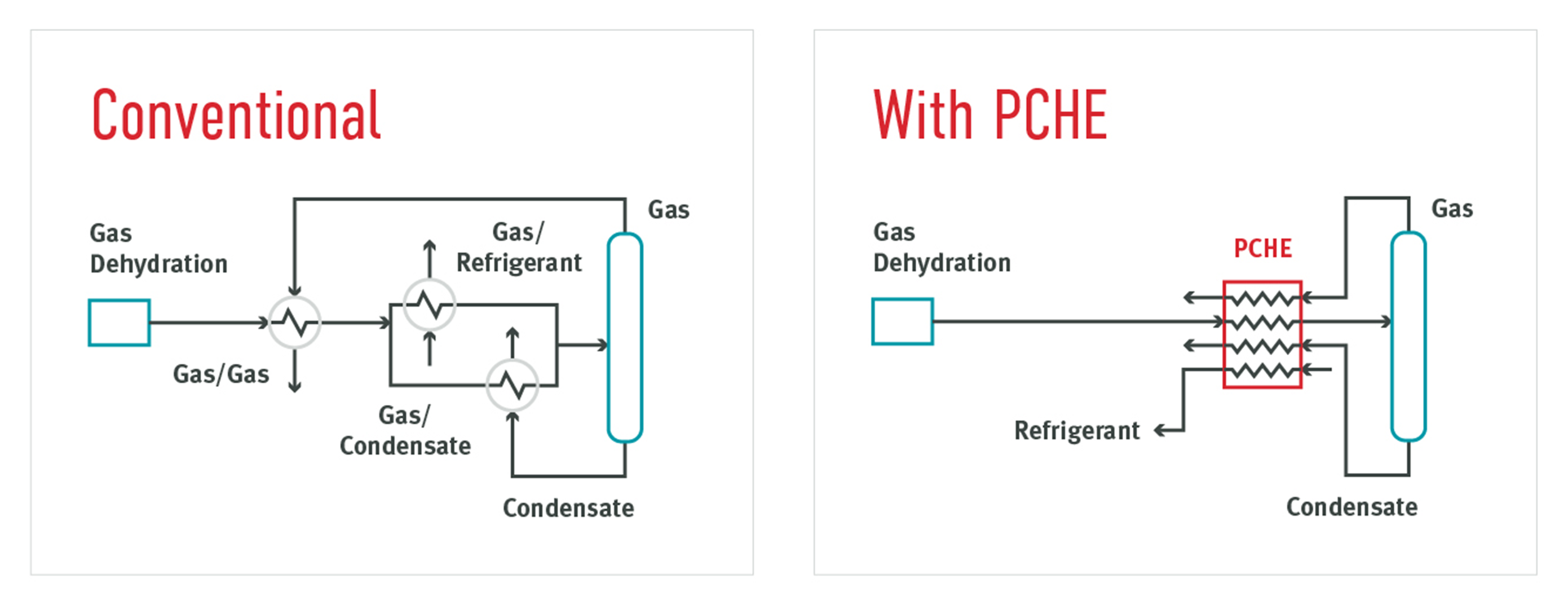

Due to the unique way in which Heatric exchangers are constructed by utilising distinct flow channels and sectioned exchanger cores – units can be designed to combine multiple integrated processes into a single multifunctional unit. This leads to substantial savings in terms of space, weight and operations.

Combining multiple flows and functionalities such as this single 1.4MW, 66Bar gas/gas, gas/condensate gas/refrigerant unit replacing 3 conventional units.

Provide the ability to create homogeneous mixing of multiple flows preventing potential issues with maldistribution found in traditional units.

This example shows the two-phase inlet approach taken by Heatric for Glycol injection into a gas stream for hydrate suppression.

Due to diffusion bonded exchangers having very discreet seperable fluid channels and with the ability to provide units with multi-sectioned cores and/or headers, Heatric can design units which can be maintained online without shutdown in situations where frozen glycol, wax or hydrates may have blocked the unit.

This example shows a gas/gas dewpointing PCHE exchanger where the header has been split into multiple sections which can then be de-rimed without shutdown.

Method:

For more information, or to find out how Heatric’s bespoke PCHEs can support your system, send a message directly through the enquiry page or contact Heatric on:

+44 (0) 1202 627 000

Heatric, a division of the Parker Hannifin Filtration Group, is a global leader in Printed Circuit Heat Exchangers (PCHEs). Heatric PCHEs are high performance, compact heat exchangers with applications across the energy industry; in oil and gas, power generation, marine, and clean technology systems. Each Heatric PCHE is bespoke to suit customer specifications and deliver maximum operational efficiency and performance. As technology pioneers with decades of design, manufacture

and operational experience, Heatric have the technical expertise to enable your innovation.