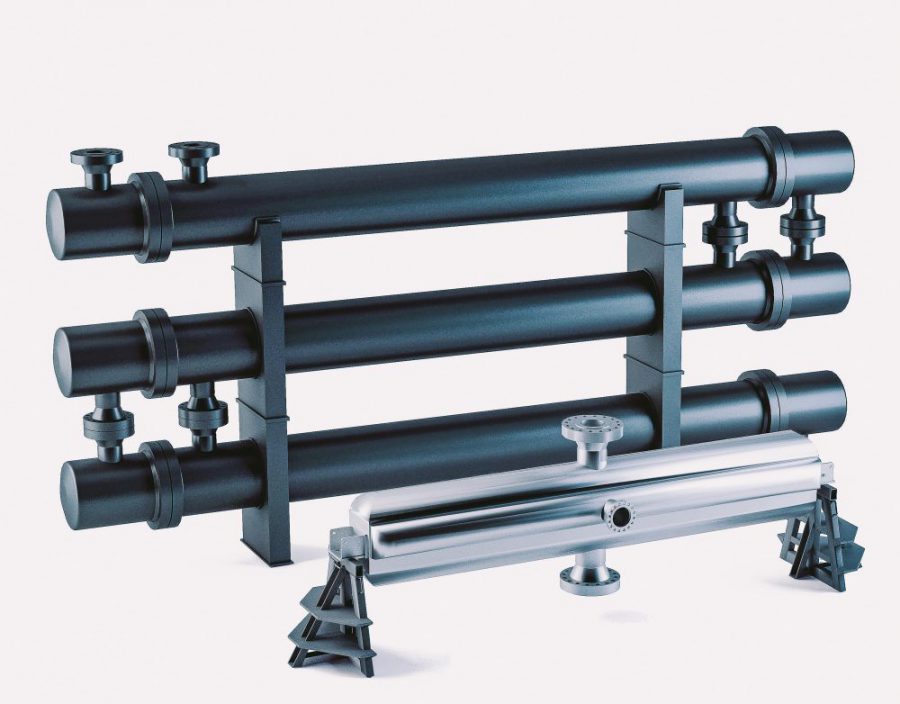

The exceptionally high heat transfer efficiency-to-volume ratio provided by Heatric’s Printed Circuit Heat Exchangers (PCHEs) is one of the most profound benefits to utilising this technology.

PCHEs provide a reduction in the unit’s overall footprint, volume and weight by up to 85% when compared to traditional technologies such as shell and tube, and generate significant cost savings in the following areas:

Heatric PCHEs also offer significant improvements to the logistical aspects of deploying heat exchangers in a system, including installation and relocation, due to the significant size reduction the technology offers.

As a benefit of the diffusion bonding process used in the manufacturing of Heatric’s PCHEs, Heatric is able to integrate complex networks of internal flow passages. These intricate flow paths provide high-performance heat-transfer capabilities that are unachievable through traditional heat transfer technologies.

“It has been estimated that the employment of Heatric Printed Circuit Heat Exchangers in the Pagerungan Gas Processing facility has saved U.S. $10.4 MM in total capital costs over what would have required if conventional shell and tube units had been utilized instead.”

Derek White-Stevens, ARCO International Oil & Gas, Pagarungan project

To discuss the needs of your project, or for more information regarding the benefits of Heatric’s compact heat exchangers, send a message directly through the enquiry page or contact Heatric on:

+44 (0) 1202 627 000

Heatric, a division of the Parker Hannifin Filtration Group, is a global leader in Printed Circuit Heat Exchangers (PCHEs). Heatric PCHEs are high performance, compact heat exchangers with applications across the energy industry; in oil and gas, power generation, marine, and clean technology systems. Each Heatric PCHE is bespoke to suit customer specifications and deliver maximum operational efficiency and performance. As technology pioneers with decades of design, manufacture

and operational experience, Heatric have the technical expertise to enable your innovation.